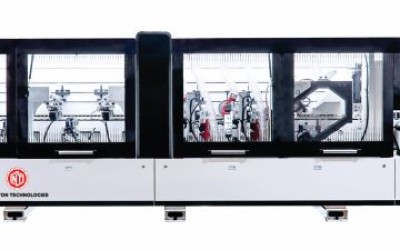

The NT48 series is mainly used for the processing and production of panel furniture cabinets and door panels; it can quickly drill holes, slot and cut materials, and can process common panel furniture two-in-one and three-in-one connector installation holes , has the function of processing some types of invisible connectors; this machine is equipped with a high-power automatic tool-changing spindle and a Linear-type tool magazine, which is suitable for diversified and complex product processing or diverse processing.

Advantage:

- It is applicable to the production process of conventional panel furniture, TV cabinet, the process of invisible parts, modeling and engraving, etc.

- 9.0KW high-power air-cooled tool-changing spindle, suitable for long-term high-speed cutting and blanking of cabinets, as well as engraving and milling of various shapes.

- Taiwan SYNTEC 60CB humanized control system, simple operation, good stability, fast data processing speed, and more accurate signal feedback.

- The bed is made of thick-walled square steel and laser cutting blanking, welded by robot welding system, tempered and aging treated, and processed by large-scale gantry milling and fine milling.

- During the production process of the whole machine and before leaving the factory, it has undergone strict quality inspection control and test machine processing tests to ensure that the back plate groove and the holes on the front and back are accurate.

Model NT48 Working size 1200 x 2800mm Structure of Table Multi-zone vacuum adsorption table Traveling speed 65m / min Air pressure > 6.5kgf/cm Type of Transmission XY Axis Rack, Z axis Screw Working voltage AC380/3PH/50Hz Driving System Servo Drive Total power 26KW Parameters of Spindle 9KW/2400RPM Total weight 2800Kg Total Capacity 0~26m/min Boundary dimension 4100X2200X2400MM

-(1)-(1)-preview.jpg)