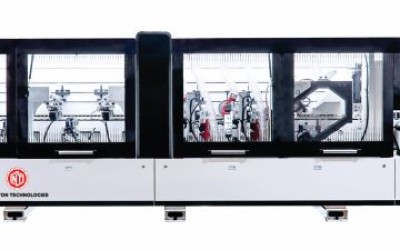

NT2 Cnc Automatic Wood Panel Mdf Furniture Cabinet Boring Horizontal Edge Side Hole Drilling Machine:

The machine is simple to operate and has high processing efficiency. It supports the processing of traditional three-in-one, two-in-one, and invisible sheet connection methods. Suitable for panel furniture, blister door panels, tables and chairs, cabinets, doors and windows and other industries.

The NT2 CNC side hole machine for woodworking supports two processing modes: scanning and infrared induction. It can quickly realize side punching and milling grooves on the workpiece. It is an economical basic equipment.

The CNC horizontal single-row drilling machine can drill horizontal holes through automatic induction of vertical holes. The drilling speed is fast, the efficiency is high, and zero-error processing is achieved.

NT-2 CNC horizontal drilling machine is an economical and practical horizontal drilling equipment for panel furniture. It can be combined with a cutting machine to form an economical panel furniture production line.

It can replace traditional table saws and gang drills. Its biggest advantage is that it can directly scan side holes, getting rid of the traditional main boring processing method.

Specification NT2 Range of Travel 2800x50mm Rapid Moving Speed 60m/min Maximum Machining Speed 15m/min Spindle Parameters 2.2Kw/18000RPM Type of Transmission X-Axis Rack, Z-Axis Screw Working Voltage AC380/3PH/50Hz Total Power 4KW Total Weight 1200Kg Overall Size 3400x1200x1500mm

-(1)-(1)-preview.jpg)