🔹 NC Panel Saw

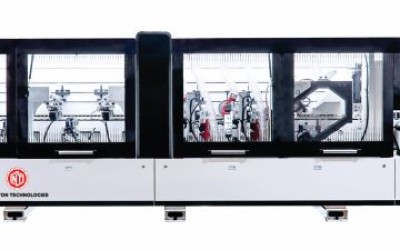

🔹 NC Panel Saw is a woodworking machine used for cutting large panels (like MDF, plywood, particle board, laminated boards) into smaller, precise sizes.

🔹 It is equipped with a CNC/NC controller that allows the operator to set dimensions on a digital screen, and the saw automatically performs accurate, repeatable cuts.

🔹 Mostly used in furniture manufacturing, modular kitchens, interior works, and panel processing units.

🔹 Key benefits:

High precision & straight cutting

Reduced wastage of material

Faster production compared to manual saws

Operator-friendly with less physical effort

👉 There are two main types:

Manual NC Panel Saw (semi-automatic with digital control)

CNC Beam Saw (fully automatic, higher-end, computer-controlled)

🔹 NC Controlled Panel Saw – Technical Specifications

1. Cutting Capacity

Max cutting length: 2,600 mm / 3,200 mm (varies by model)

Max cutting thickness: 60 – 120 mm (single cut)

Max cutting width: 2,600 mm / 3,200 mm

2. Saw Unit

Main saw motor power: 7.5 – 11 kW

Main saw blade diameter: Ø 300 – 380 mm

Main saw speed: 3,000 – 5,000 RPM

Scoring saw blade diameter: Ø 120 – 180 mm

Scoring motor power: 1.1 – 1.5 kW

Scoring saw speed: 8,000 – 9,000 RPM

3. Control System

NC touch screen control with cutting program input

Memory for multiple cutting programs

Optimized cutting sequence for reduced wastage

Auto positioning of back fence

4. Feeding & Pusher System

Automatic pusher carriage with servo motor drive

Feeding speed: 0–60 m/min adjustable

Return speed: up to 80 m/min

High precision ±0.1 mm

5. Table & Support

Air flotation table for easy material movement

Side tables for large panel support

Heavy-duty steel body construction

6. Dust Collection

Dust extraction ports: Ø 80–120 mm

Efficient suction at main saw and scoring unit

7. Safety Features

Emergency stop switches

Safety guards over saw blade

Overload protection

-(1)-(1).png)

-(1)-(1)-preview.jpg)